I was asked by moderators on another forum (but thought I'll post it here too) to give some input on the site’s biocube thread, and when asked, as per my usual modus operandi when asked to do something, words like fastidious, thorough and tedious to the point of painfulness come to mind…. Before I start, please note that I have no affiliation with the manufacturer or any distributors of the product. I have never received any free samples or monetary remuneration from the company and all tests done with their product has been done at my expense and with stock purchased at retail price. My opinions and thoughts about the product might come across as biased, which I am happy to admit, as it is seldom that I have found a product in this hobby which will do exactly as claimed, as well as some more.

Use it, lose it, the choice is yours…..

Orca Nitra Guard Bio Cubes, my thoughts…..

Ever so often, a new buzz word starts doing the rounds amongst hobbyists, a new concept, a new product, or the re-emergence of something from years gone by. It seems the buzz has now started spreading internationally too with recent posts on Reef Builders. Slowly but surely, I have (not so quietly) observed the emergence of yet another buzz word on the South African Marine Aquarist Forums, namely Nitra-Guard Bio-Cubes.

I first came across the product towards the end of 2011, whilst discussing setup and filtration options for my new tank with an industry wholesaler, Liaquat Sain from Aquality distribution. He showed me a sample of this product, reminiscent of cubed feta cheese, just a lot harder. Due to space and budgetary constraints, a DSB or zeolite methodologies were not an option for nutrient control in my new setup, and after a brief explanation of the product and reading the label, I was tempted. Having wasted literally tens of thousands in this hobby on products which simply don’t do what they claim, or do it effectively, I was still slightly sceptical, even though I knew Liaquat as someone to give solid advice based on research and not motivated by sales. When the time for filtration setup arrived, I thought to myself: Worst case, I would have wasted another few hundred rand in this hobby, but fortunately I have some knowledge on how to revert to other methodologies should this one turn out to be bogus….

The recommended dose on the label read 1ml per litre for lightly stocked tanks and 3ml for heavy stocked tanks, so, being a new system and wanting to stock it fast and relatively heavy, I decided to go with 2ml per litre… I placed it in a regular hang on filter, filled my tank with water, added some fresh uncured live rock, as well as a bit of cured stuff from a fellow hobbyist and waited for the cycle to start…..

Few days, No ammonia, no nitrites and no nitrates, weird…,but waited a few more days and still nothing…… Thought I might be on to something here and decided to start adding fish… Started with a huge Yellow Tang from my previous tank.. two days, no detectable nitrates, 5 Chromis, two days… nothing, Midas Blenny……. Few more damsels…… still nothing…. Added corals, and still nothing…. Knowing that my Phosphate would creep up, and not having reagents for my photometer, I decided to get some phosphate remover. With at this stage still only “suspected” good results with Orca Cubes, I tried some of their PO4 remover, as it was affordable and simply being a GFH I knew it would at least do something… Christmas time came around and I went away for a one week holiday, leaving my neighbour in charge of the tank with some concern regarding overfeeding and nutrient levels, but I needed the break and living out in the sticks one does not really have too many options in terms of tank sitters. On my return, the first thing I noticed besides the fact that all the fish were still swimming, was that what was half a Ocean Nutrition tub of pellets prior to my departure, was now empty. A few colourful words and thoughts about what part of a pinch in the am and a pinch in the am does he not understand…. Grabbed my test kits and totally flabbergasted, my NO3 was still not measurable…. I got another kit, and the result was the same: no colour change indicating presence of nitrates.

I was impressed…. Finally, a product which does as advertised, no more dosing of bacterial cultures or carbon sources, no more worrying about nitrates….

During routine maintenance, I checked on the GFH in another hang on, only to discover that it had clumped quite badly. Not being able to find satisfactory information on this, I decided to contact the company who manufactures it. I found an email on the web, and sent a mail, which was answered within a few hours by a phone call from Mark Nel, owner of OAL and developer of the company. Yes, I was impressed, an owner of a company making a product I use contacting me…. Did someone say service?? After explaining the clumping in the GFH, I mentioned to him about how impressed I am with his cubes, resulting in a lengthy conversation about its development, what makes it different and the basics of how it works:

My perception that it was just another form of solid carbon, was quickly dispelled when I was given a brief breakdown of the science behind its development. In order to understand why this product cannot be seen in the same light as the nitrate reducing pellets available in the trade, one has to understand what each product is.

Let us look at pellets:

Pellets were not developed for the aquarium industry. They were developed as a material to

1.) make plastic biodegradable (or at least speed up the process)

2.) utilize renewable sources of raw materials instead of fossil fuels, hence the development of PLA:

PLA (polylactic acid) is a plastic produced from resources that can be renewed on an annual basis, such as sugar beet, sugar cane, wheat, maize and cellulose.

The PLA manufacturing process includes biotechnology activity in the sucrose (sugar) or glucose extraction phase before transformation by fermentation (using a micro-organism) into lactic acid. This lactic acid is then chemically transformed into PLA.

PLA has been known as a polymer for many years in medical applications, such as stitches, orthopedic or galenical pins. This sector of application was developed on the basis of the biocompatibility between humans and this polymer, which is obtained from lactic acid. Due to technological developments and optimisations of the procedure, PLA is now available on commodity markets, such as packaging, disposable objects, fibers and more. Many product developments are ongoing and should enable, in the near future, the use of PLA in such sustainable applications as the automotive industry, floor coverings and electronics.

In addition to the conventional methods, PLA has the distinctive feature of increasing end-of-life management options. PLA from renewable raw materials is also biodegradable and compostable. This is one of the options for managing the end of life of this biosource polymer.

Excerpt taken from Futerro

Truth of the matter is, the pellets are derived from the same product which is used in manufacture of disposable and biodegradable “plastic” cutlery / plastic bags. This is not meant to shed a negative light on pellets, as the pellets do contain a carbon source (in the form of starch) and will therefore harbour microorganisms which utilize the carbohydrate molecules to remove nutrients from our tanks. Bottom line, they do work if employed correctly.

One has to ask why simply not just import biodegradable pellets from their country of origin, somehow “boost them in terms of carbon content,” repackage and market at a rock bottom price? When asked, the developer of orca Bio Cubes gave me a rather interesting answer:

“‘We either find a way…or we make one’

There was once a famous general known as Hannibal Barca. He gave the Romans the worst defeat they ever had at the battle of Cannae where he killed more than 80 000 of them. That strategy, known as the perfect defeat, is still taught to generals today and was even used in Operation Desert Storm by General Norman Schwarzkopf. When Hannibal Barca crossed the Alps with elephants, he was quoted as famously saying ‘we either find a way…or we make one’ This saying has been the backbone of all my success. He was eventually defeated by the Romans who used another strategy which can be expressed simply as ‘you are only defeated when you admit that you are defeated’ this strategy has always carried me through my darkest times.

I was looking at another form of NO3 removal after it became almost impossible to get the ion exchange resin that works in seawater from the manufacturers. Price issues, importing hassles etc… all started to become a little too much. I had to find another way.

I looked at pellets that were made in the USA and China and noticed that they were adding starch into the pellets.

It would need a real form and quantity of carbon in order for the product to work. All these pellets are being bought from suppliers who will make them to a certain spec and that would not change.

Unfortunately, due to the high amount of heat required to blow mould, incorporating too much starch would burn the starch and also significantly reduce the tensile strength of the plastic bags. We are therefore left with a product with only limited carbohydrate fuels in the mix.

In order for me to come up with something superior, I would have to find a way to get more carbohydrates into the product

I set to work and of course, I had found a way, but, did this way lead me to where I wanted to be? It was at this point that I realized that if I “found a way”, I would be like the rest of the companies that were selling something inferior in performance. Would I want to buy biodegradable pellets from the Chinese and then repackage them. I did not want that. I wanted a product that would speak for itself. It was blatantly clear, a way had already been found and the other companies were using it already. I would need to “MAKE a way” if I am to become successful and to stand out of the crowd. Making my own way would be the only way forward.”

Easy to see how Mark’s words can ruffle a few feathers in the industry, but it seems like he has a valid point…..

http://www.alibaba.com/trade/search?SearchText=biodegradable+resin&IndexArea=product_en&fsb=y

Whether these pellets are the same as used in the aquarium trade (i.e. unchanged), or whether they are changed to incorporate more of a carbon source and to what degree it is possible to change them, only thorough research will reveal….

Anyway, the intention of this article is not to play a proven form of “solid carbon dosing” against what is perceived by aquarists to be another form of carbon dosing…… On this, Mark comments:

“The truth is if you have a carbohydrate source, nitrogen and phosphorous, you will make biomass. This is the truth, but, if the carbohydrate source were limited or not biologically available, that would change that truth. This truth would become the reality of the matter and this reality is either failure or limited results. I often hear people talk about BIO-Cubes as “it’s just another form of carbon dosing” or “if it was such a good product, the big guns would already have it” The truth is that yes, those pellets do contain carbohydrates, but, due to the limited amount and low surface area, success is limited and that is the reality.

BIO-Cubes have been completely designed for use in an aquarium and are not a derivative of other industries. Every time I see posts like “it’s another version of ….pellets” I immediately realize that that person has no knowledge of what he is talking about. Unfortunately, I can prove that this person is ignorant because simply put, you can’t make plastic bags out of BIO-Cubes. The truth is they do contain similar ingredients, but, the reality is that BIO-Cubes is the only media of its kind that was designed for use in aquariums. This is a statement that I will uphold until the day comes that someone can successfully manufacture plastic bags using BIO-Cubes.”

So…… What exactly are bio cubes?

With a scientific and aqua culture background, and being an avid body builder, Mark is well aware of the function of carbohydrates in providing your body with glycogen required to burn as fuel for the muscles. All of this conversion from starch to glycogen required some work on the part of the body. Why not just supply them directly with what they need?

Utilizing a modified glucose as found in a two part drink developed for bodybuilders, called “bang bang,” whereby the body is provided glycogen in a faster way than relying on the bodies conversion of starch to provide energy,(Interestingly, also developed by Mark.) he researched ways to incorporate the modified glucose into a suitable aquarium substrate.

But this simply was not good enough….

Now, we all know that increasing the surface area in our filters result in a more effective filter that removes ammonia and nitrite more effectively. In order to make the product perform better, a higher surface area would be required. Increased surface area would house more bacteria, more bacteria would require more nutrients such as NO3 and PO4 which would increase the desired results.

Whilst researching an excellent quality of activated carbon for his company, when reading about some activated carbons that has a total surface area that is over 2 000m2 per gram, the idea struck him that outer form of the structure would not matter as long as the inner matrix of the structure had what was needed.

He set to work creating large cubes that had large pores in them. The larger pores allowed the biomass to be ejected efficiently, but, still created a massive surface area to give the product that unfair advantage that it required to be considered a superior performing product.

At the end of the day, the proof is in the pudding: Even though the results from reefers here and internationally who have used this product show definite results, pictures speak a thousand words:

Some Potassium Nitrate & Potassium Phosphate was added to a tank set up for this test using mature reef tank water. Levels were raised to around 100mg/lts (ppm) and the PO4 levels were between 8mg/lts and 10mg/lts (ppm), basically, off the chart. No livestock was added to the tank, water circulation was by means of an air-stone and the cubes were placed in a small hang on filter. About 20 ml (a tot glass) of cubes from my reef tank was used to seed the fresh cubes.

Total water volume of tank: 60L

Total quantity of cubes: Approximately 50ml (I know this is approximately ten fold the recommended dose, but then again, bear in mind that the nutrient levels were several magnitude higher than those expected to be found in well kept tanks.)

Day 1

NO3:

PO4:

There was no marked change during the first few days, which left me a bit disappointed, as I really though the bacteria would have a field day with the new real estate and nutrients to boot.

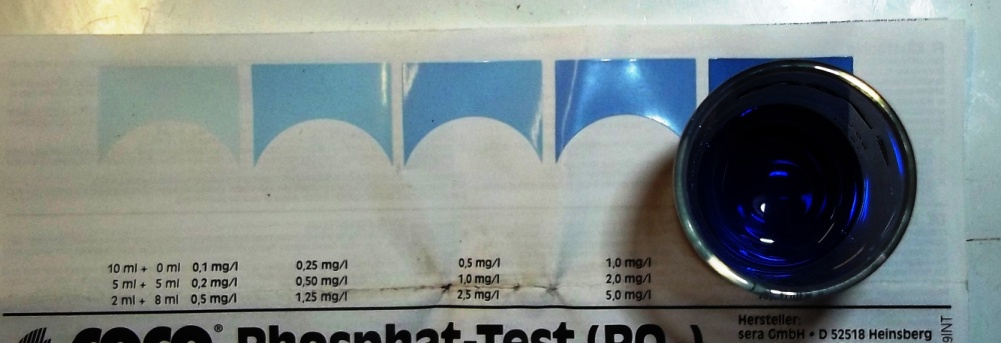

However, after day eight, things suddenly went downhill….. in a good way (Please note that PO4 sample had to be diluted 3 times:

Day 9:

Day 12:

Actual PO4 reading as per Hanna photometer: 0.08, where, like in my tank, it bottomed out and would not go down without some additional help…. Anyway, pretty powerful stuff…. So we have to ask: What exactly is going on here?

I’ll stick to the basics and try not to get too involved with electron donors / receptors, ATP, Redfield ratio, etc, besides, this is becoming a long story…

The cubes serve as a very suitable substrate for biomass colonization, due its large internal surface area, as well as the vast amount of biologically available carbon to serve as an energy source. Pretty much the same reason aquarists started adding vodka to their tanks: suspected shortage of biologically available carbon.

Please bear in mind that we are not dealing with the “traditionally accepted” final step in the nitrogen cycle, but something all together different. In the “traditionally accepted” final stage of de-nitrification, anaerobic conditions are required, which harbour bacteria which strip the oxygen molecules from the nitrate ion (which is made up of nitrogen and oxygen).

We are dealing with a process which occurs in an oxygen rich environment, in fact, the more oxygen, the better these cubes work it seems…… More eyebrows raising????

The reality is, that all living organisms require 4 essential things, i.e. Nitrogen, to use in synthesis of structural components and Inorganic phosphorus in the form of the phosphate PO3−4 is required for all known forms of Life, playing a major role in biological molecules such as DNA and RNA where it forms part of the structural framework of these molecules. Living cells also use phosphate to transport cellular energy in the form of adenosine triphosphate (ATP). Nearly every cellular process that uses energy obtains it in the form of ATP. ATP is also important for phosphorylation, a key regulatory event in cells. Phospholipids are the main structural components of all cellular membranes. Calcium phosphate salts assist in stiffening bones.

And lastly, they require Carbon as an energy source and oxygen to well, yes…. BREATHE!

(in fact there are a few more elements they require, but that is beyond the scope of this article)

In essence, this is exactly what bio cubes are: A perfect real estate for bacteria to colonise, as it provides huge areas, filled with lots of free food which is locked up in this “real estate”, yet is biologically available to them. Oxygen is supplied by the well oxygenated water flowing past from the tank and Nitrogen and Phosphorous is supplied by means of dissolved organics in our tanks, i.e. NO3 and PO4. As the bacteria “discover” this massive pieces of real estate with the nutrient (carbon) which is mostly limiting now available in huge quantities, to be honest, in an extremely easily available form, they are hell bent on colonising it…. Wouldn’t you be? However, to colonise, they need Nitrogen and Phosphorous as mentioned above….. With these elements constantly passing by as dissolved organics in the water column, they are now ready to procreate, and if there is one thing I remember from those micro biology lectures at college, it is the rate at which bacteria can multiply, given ideal circumstances……. It is called exponential growth….. And as they multiply, they turn dissolved nutrients into biomass.

Once any of the required components (O2,N,P or C) run out, the bacteria will stop multiplying, as they require all of them and in specific ratios. Once this occurs, the bacteria will go into a dormant state, until the limiting nutrient is available, at which point they will again take up C,N,P and O2. I have found that with this product, my PO4 level dropped up to a point, where after it will not drop any more. This is not due to any shortfall of the product, but simply due to the laws of nature. Remember that ORCA BIO CUBES were not advertised as removing PO4, it was developed and marketed as a Nitrate removing substrate. The fact that it removes PO4, is simply an added bonus, thanks to the laws of nature, i.e. the ratio of CNP uptake by biomass, Redfield Ratio ring a bell?

What is important to remember, is that the input of food into our aquaria is often skewed when compared to the biological uptake ratio of Nitrogen to Phosphorous. Truth is, we mostly add more PO4 than the biomass can remove, as it will reach a point where there is no more Nitrate available for bacteria to use in their “expansion project.” This fact is relative to any biological method of nutrient removal, regardless of what clever marketing salesmen may have you believe… Nature has laws and they cannot be changed…. Manipulated, but not changed…. I strongly suspect that this is probably the primary reason why the product is not marketed as a Nitrate and Phosphate removal product, but rather just as a Nitrate removal system.

In saying that, I by chance stumbled across a method in which this product can be used to reduce the PO4 concentration, even after its removal due to Nitrogen limitation is reached. This is however something for a much more advanced article, but as a hint, I urge the reader to google EBPR.

If you are still reading at this point, I strongly urge you to not just take my word for it, do a search on the internet forums and discuss the results hobbyists have had using this product. Do some research on assimilation of CNP by marine bacteria, availability of carbon as a fuel for bacterial growth, etc. Start at the onset of vodka dosing a few years back and follow the progression into solid carbon substrates and you will find that ORCA BIO CUBES are heading in the right direction, or should I say, leading the way….

Use it, lose it, the choice is yours…..

Orca Nitra Guard Bio Cubes, my thoughts…..

Ever so often, a new buzz word starts doing the rounds amongst hobbyists, a new concept, a new product, or the re-emergence of something from years gone by. It seems the buzz has now started spreading internationally too with recent posts on Reef Builders. Slowly but surely, I have (not so quietly) observed the emergence of yet another buzz word on the South African Marine Aquarist Forums, namely Nitra-Guard Bio-Cubes.

I first came across the product towards the end of 2011, whilst discussing setup and filtration options for my new tank with an industry wholesaler, Liaquat Sain from Aquality distribution. He showed me a sample of this product, reminiscent of cubed feta cheese, just a lot harder. Due to space and budgetary constraints, a DSB or zeolite methodologies were not an option for nutrient control in my new setup, and after a brief explanation of the product and reading the label, I was tempted. Having wasted literally tens of thousands in this hobby on products which simply don’t do what they claim, or do it effectively, I was still slightly sceptical, even though I knew Liaquat as someone to give solid advice based on research and not motivated by sales. When the time for filtration setup arrived, I thought to myself: Worst case, I would have wasted another few hundred rand in this hobby, but fortunately I have some knowledge on how to revert to other methodologies should this one turn out to be bogus….

The recommended dose on the label read 1ml per litre for lightly stocked tanks and 3ml for heavy stocked tanks, so, being a new system and wanting to stock it fast and relatively heavy, I decided to go with 2ml per litre… I placed it in a regular hang on filter, filled my tank with water, added some fresh uncured live rock, as well as a bit of cured stuff from a fellow hobbyist and waited for the cycle to start…..

Few days, No ammonia, no nitrites and no nitrates, weird…,but waited a few more days and still nothing…… Thought I might be on to something here and decided to start adding fish… Started with a huge Yellow Tang from my previous tank.. two days, no detectable nitrates, 5 Chromis, two days… nothing, Midas Blenny……. Few more damsels…… still nothing…. Added corals, and still nothing…. Knowing that my Phosphate would creep up, and not having reagents for my photometer, I decided to get some phosphate remover. With at this stage still only “suspected” good results with Orca Cubes, I tried some of their PO4 remover, as it was affordable and simply being a GFH I knew it would at least do something… Christmas time came around and I went away for a one week holiday, leaving my neighbour in charge of the tank with some concern regarding overfeeding and nutrient levels, but I needed the break and living out in the sticks one does not really have too many options in terms of tank sitters. On my return, the first thing I noticed besides the fact that all the fish were still swimming, was that what was half a Ocean Nutrition tub of pellets prior to my departure, was now empty. A few colourful words and thoughts about what part of a pinch in the am and a pinch in the am does he not understand…. Grabbed my test kits and totally flabbergasted, my NO3 was still not measurable…. I got another kit, and the result was the same: no colour change indicating presence of nitrates.

I was impressed…. Finally, a product which does as advertised, no more dosing of bacterial cultures or carbon sources, no more worrying about nitrates….

During routine maintenance, I checked on the GFH in another hang on, only to discover that it had clumped quite badly. Not being able to find satisfactory information on this, I decided to contact the company who manufactures it. I found an email on the web, and sent a mail, which was answered within a few hours by a phone call from Mark Nel, owner of OAL and developer of the company. Yes, I was impressed, an owner of a company making a product I use contacting me…. Did someone say service?? After explaining the clumping in the GFH, I mentioned to him about how impressed I am with his cubes, resulting in a lengthy conversation about its development, what makes it different and the basics of how it works:

My perception that it was just another form of solid carbon, was quickly dispelled when I was given a brief breakdown of the science behind its development. In order to understand why this product cannot be seen in the same light as the nitrate reducing pellets available in the trade, one has to understand what each product is.

Let us look at pellets:

Pellets were not developed for the aquarium industry. They were developed as a material to

1.) make plastic biodegradable (or at least speed up the process)

2.) utilize renewable sources of raw materials instead of fossil fuels, hence the development of PLA:

PLA (polylactic acid) is a plastic produced from resources that can be renewed on an annual basis, such as sugar beet, sugar cane, wheat, maize and cellulose.

The PLA manufacturing process includes biotechnology activity in the sucrose (sugar) or glucose extraction phase before transformation by fermentation (using a micro-organism) into lactic acid. This lactic acid is then chemically transformed into PLA.

PLA has been known as a polymer for many years in medical applications, such as stitches, orthopedic or galenical pins. This sector of application was developed on the basis of the biocompatibility between humans and this polymer, which is obtained from lactic acid. Due to technological developments and optimisations of the procedure, PLA is now available on commodity markets, such as packaging, disposable objects, fibers and more. Many product developments are ongoing and should enable, in the near future, the use of PLA in such sustainable applications as the automotive industry, floor coverings and electronics.

In addition to the conventional methods, PLA has the distinctive feature of increasing end-of-life management options. PLA from renewable raw materials is also biodegradable and compostable. This is one of the options for managing the end of life of this biosource polymer.

Excerpt taken from Futerro

Truth of the matter is, the pellets are derived from the same product which is used in manufacture of disposable and biodegradable “plastic” cutlery / plastic bags. This is not meant to shed a negative light on pellets, as the pellets do contain a carbon source (in the form of starch) and will therefore harbour microorganisms which utilize the carbohydrate molecules to remove nutrients from our tanks. Bottom line, they do work if employed correctly.

One has to ask why simply not just import biodegradable pellets from their country of origin, somehow “boost them in terms of carbon content,” repackage and market at a rock bottom price? When asked, the developer of orca Bio Cubes gave me a rather interesting answer:

“‘We either find a way…or we make one’

There was once a famous general known as Hannibal Barca. He gave the Romans the worst defeat they ever had at the battle of Cannae where he killed more than 80 000 of them. That strategy, known as the perfect defeat, is still taught to generals today and was even used in Operation Desert Storm by General Norman Schwarzkopf. When Hannibal Barca crossed the Alps with elephants, he was quoted as famously saying ‘we either find a way…or we make one’ This saying has been the backbone of all my success. He was eventually defeated by the Romans who used another strategy which can be expressed simply as ‘you are only defeated when you admit that you are defeated’ this strategy has always carried me through my darkest times.

I was looking at another form of NO3 removal after it became almost impossible to get the ion exchange resin that works in seawater from the manufacturers. Price issues, importing hassles etc… all started to become a little too much. I had to find another way.

I looked at pellets that were made in the USA and China and noticed that they were adding starch into the pellets.

It would need a real form and quantity of carbon in order for the product to work. All these pellets are being bought from suppliers who will make them to a certain spec and that would not change.

Unfortunately, due to the high amount of heat required to blow mould, incorporating too much starch would burn the starch and also significantly reduce the tensile strength of the plastic bags. We are therefore left with a product with only limited carbohydrate fuels in the mix.

In order for me to come up with something superior, I would have to find a way to get more carbohydrates into the product

I set to work and of course, I had found a way, but, did this way lead me to where I wanted to be? It was at this point that I realized that if I “found a way”, I would be like the rest of the companies that were selling something inferior in performance. Would I want to buy biodegradable pellets from the Chinese and then repackage them. I did not want that. I wanted a product that would speak for itself. It was blatantly clear, a way had already been found and the other companies were using it already. I would need to “MAKE a way” if I am to become successful and to stand out of the crowd. Making my own way would be the only way forward.”

Easy to see how Mark’s words can ruffle a few feathers in the industry, but it seems like he has a valid point…..

http://www.alibaba.com/trade/search?SearchText=biodegradable+resin&IndexArea=product_en&fsb=y

Whether these pellets are the same as used in the aquarium trade (i.e. unchanged), or whether they are changed to incorporate more of a carbon source and to what degree it is possible to change them, only thorough research will reveal….

Anyway, the intention of this article is not to play a proven form of “solid carbon dosing” against what is perceived by aquarists to be another form of carbon dosing…… On this, Mark comments:

“The truth is if you have a carbohydrate source, nitrogen and phosphorous, you will make biomass. This is the truth, but, if the carbohydrate source were limited or not biologically available, that would change that truth. This truth would become the reality of the matter and this reality is either failure or limited results. I often hear people talk about BIO-Cubes as “it’s just another form of carbon dosing” or “if it was such a good product, the big guns would already have it” The truth is that yes, those pellets do contain carbohydrates, but, due to the limited amount and low surface area, success is limited and that is the reality.

BIO-Cubes have been completely designed for use in an aquarium and are not a derivative of other industries. Every time I see posts like “it’s another version of ….pellets” I immediately realize that that person has no knowledge of what he is talking about. Unfortunately, I can prove that this person is ignorant because simply put, you can’t make plastic bags out of BIO-Cubes. The truth is they do contain similar ingredients, but, the reality is that BIO-Cubes is the only media of its kind that was designed for use in aquariums. This is a statement that I will uphold until the day comes that someone can successfully manufacture plastic bags using BIO-Cubes.”

So…… What exactly are bio cubes?

With a scientific and aqua culture background, and being an avid body builder, Mark is well aware of the function of carbohydrates in providing your body with glycogen required to burn as fuel for the muscles. All of this conversion from starch to glycogen required some work on the part of the body. Why not just supply them directly with what they need?

Utilizing a modified glucose as found in a two part drink developed for bodybuilders, called “bang bang,” whereby the body is provided glycogen in a faster way than relying on the bodies conversion of starch to provide energy,(Interestingly, also developed by Mark.) he researched ways to incorporate the modified glucose into a suitable aquarium substrate.

But this simply was not good enough….

Now, we all know that increasing the surface area in our filters result in a more effective filter that removes ammonia and nitrite more effectively. In order to make the product perform better, a higher surface area would be required. Increased surface area would house more bacteria, more bacteria would require more nutrients such as NO3 and PO4 which would increase the desired results.

Whilst researching an excellent quality of activated carbon for his company, when reading about some activated carbons that has a total surface area that is over 2 000m2 per gram, the idea struck him that outer form of the structure would not matter as long as the inner matrix of the structure had what was needed.

He set to work creating large cubes that had large pores in them. The larger pores allowed the biomass to be ejected efficiently, but, still created a massive surface area to give the product that unfair advantage that it required to be considered a superior performing product.

At the end of the day, the proof is in the pudding: Even though the results from reefers here and internationally who have used this product show definite results, pictures speak a thousand words:

Some Potassium Nitrate & Potassium Phosphate was added to a tank set up for this test using mature reef tank water. Levels were raised to around 100mg/lts (ppm) and the PO4 levels were between 8mg/lts and 10mg/lts (ppm), basically, off the chart. No livestock was added to the tank, water circulation was by means of an air-stone and the cubes were placed in a small hang on filter. About 20 ml (a tot glass) of cubes from my reef tank was used to seed the fresh cubes.

Total water volume of tank: 60L

Total quantity of cubes: Approximately 50ml (I know this is approximately ten fold the recommended dose, but then again, bear in mind that the nutrient levels were several magnitude higher than those expected to be found in well kept tanks.)

Day 1

NO3:

PO4:

There was no marked change during the first few days, which left me a bit disappointed, as I really though the bacteria would have a field day with the new real estate and nutrients to boot.

However, after day eight, things suddenly went downhill….. in a good way (Please note that PO4 sample had to be diluted 3 times:

Day 9:

Day 12:

Actual PO4 reading as per Hanna photometer: 0.08, where, like in my tank, it bottomed out and would not go down without some additional help…. Anyway, pretty powerful stuff…. So we have to ask: What exactly is going on here?

I’ll stick to the basics and try not to get too involved with electron donors / receptors, ATP, Redfield ratio, etc, besides, this is becoming a long story…

The cubes serve as a very suitable substrate for biomass colonization, due its large internal surface area, as well as the vast amount of biologically available carbon to serve as an energy source. Pretty much the same reason aquarists started adding vodka to their tanks: suspected shortage of biologically available carbon.

Please bear in mind that we are not dealing with the “traditionally accepted” final step in the nitrogen cycle, but something all together different. In the “traditionally accepted” final stage of de-nitrification, anaerobic conditions are required, which harbour bacteria which strip the oxygen molecules from the nitrate ion (which is made up of nitrogen and oxygen).

We are dealing with a process which occurs in an oxygen rich environment, in fact, the more oxygen, the better these cubes work it seems…… More eyebrows raising????

The reality is, that all living organisms require 4 essential things, i.e. Nitrogen, to use in synthesis of structural components and Inorganic phosphorus in the form of the phosphate PO3−4 is required for all known forms of Life, playing a major role in biological molecules such as DNA and RNA where it forms part of the structural framework of these molecules. Living cells also use phosphate to transport cellular energy in the form of adenosine triphosphate (ATP). Nearly every cellular process that uses energy obtains it in the form of ATP. ATP is also important for phosphorylation, a key regulatory event in cells. Phospholipids are the main structural components of all cellular membranes. Calcium phosphate salts assist in stiffening bones.

And lastly, they require Carbon as an energy source and oxygen to well, yes…. BREATHE!

(in fact there are a few more elements they require, but that is beyond the scope of this article)

In essence, this is exactly what bio cubes are: A perfect real estate for bacteria to colonise, as it provides huge areas, filled with lots of free food which is locked up in this “real estate”, yet is biologically available to them. Oxygen is supplied by the well oxygenated water flowing past from the tank and Nitrogen and Phosphorous is supplied by means of dissolved organics in our tanks, i.e. NO3 and PO4. As the bacteria “discover” this massive pieces of real estate with the nutrient (carbon) which is mostly limiting now available in huge quantities, to be honest, in an extremely easily available form, they are hell bent on colonising it…. Wouldn’t you be? However, to colonise, they need Nitrogen and Phosphorous as mentioned above….. With these elements constantly passing by as dissolved organics in the water column, they are now ready to procreate, and if there is one thing I remember from those micro biology lectures at college, it is the rate at which bacteria can multiply, given ideal circumstances……. It is called exponential growth….. And as they multiply, they turn dissolved nutrients into biomass.

Once any of the required components (O2,N,P or C) run out, the bacteria will stop multiplying, as they require all of them and in specific ratios. Once this occurs, the bacteria will go into a dormant state, until the limiting nutrient is available, at which point they will again take up C,N,P and O2. I have found that with this product, my PO4 level dropped up to a point, where after it will not drop any more. This is not due to any shortfall of the product, but simply due to the laws of nature. Remember that ORCA BIO CUBES were not advertised as removing PO4, it was developed and marketed as a Nitrate removing substrate. The fact that it removes PO4, is simply an added bonus, thanks to the laws of nature, i.e. the ratio of CNP uptake by biomass, Redfield Ratio ring a bell?

What is important to remember, is that the input of food into our aquaria is often skewed when compared to the biological uptake ratio of Nitrogen to Phosphorous. Truth is, we mostly add more PO4 than the biomass can remove, as it will reach a point where there is no more Nitrate available for bacteria to use in their “expansion project.” This fact is relative to any biological method of nutrient removal, regardless of what clever marketing salesmen may have you believe… Nature has laws and they cannot be changed…. Manipulated, but not changed…. I strongly suspect that this is probably the primary reason why the product is not marketed as a Nitrate and Phosphate removal product, but rather just as a Nitrate removal system.

In saying that, I by chance stumbled across a method in which this product can be used to reduce the PO4 concentration, even after its removal due to Nitrogen limitation is reached. This is however something for a much more advanced article, but as a hint, I urge the reader to google EBPR.

If you are still reading at this point, I strongly urge you to not just take my word for it, do a search on the internet forums and discuss the results hobbyists have had using this product. Do some research on assimilation of CNP by marine bacteria, availability of carbon as a fuel for bacterial growth, etc. Start at the onset of vodka dosing a few years back and follow the progression into solid carbon substrates and you will find that ORCA BIO CUBES are heading in the right direction, or should I say, leading the way….

thanks

thanks